Soap Making Experiment

Observe the saponification process where fats/oils react with sodium hydroxide (lye) to form soap and glycerol. This chemical reaction is the basis of traditional soap making.

Select an oil/fat and add it to the beaker with lye solution. Stir to initiate the saponification reaction.

The Science Behind Soap Making

Saponification is the hydrolysis of an ester under basic conditions to form an alcohol and the salt of a carboxylic acid:

- Triglycerides (fats/oils) react with sodium hydroxide (lye)

- The ester bonds are broken, forming glycerol

- The fatty acid chains combine with sodium to form soap

- The reaction requires heat and thorough mixing

1. Prepare lye solution by dissolving NaOH in water

2. Heat the selected oil/fat

3. Slowly add lye solution to oils while stirring

4. Continue stirring until "trace" is achieved (mixture thickens)

5. Pour into molds and let cure for 4-6 weeks

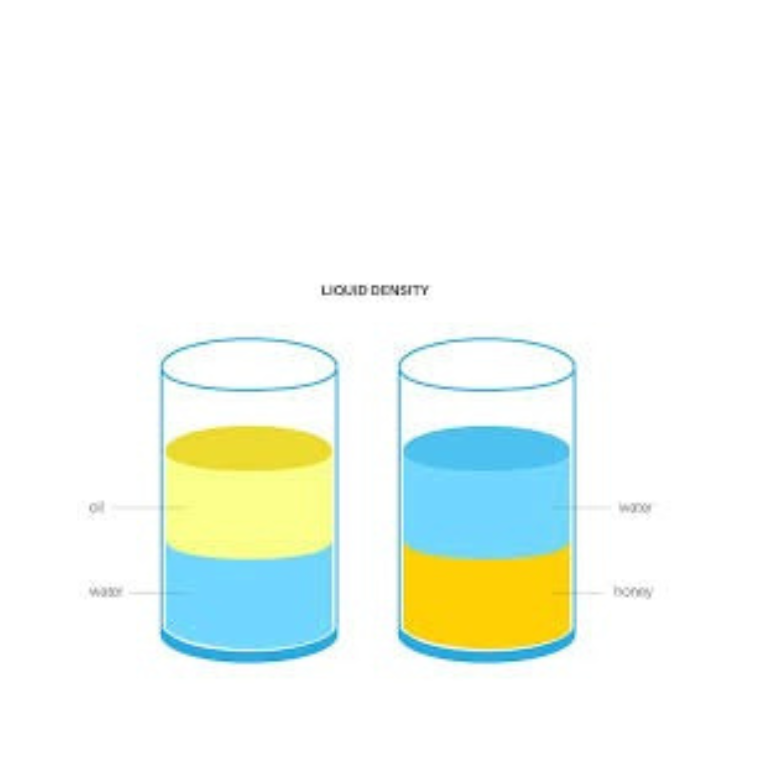

Different oils produce soaps with different properties:

- Olive Oil: Mild, moisturizing soap

- Coconut Oil: Hard, bubbly soap with cleansing properties

- Palm Oil: Hard, stable lather

- Lard: Hard, long-lasting bar with creamy lather