Making Nylon

Polymerization Demonstration

Simulate the nylon rope trick experiment demonstrating interfacial polymerization. Observe the formation of a nylon polymer strand at the interface of two immiscible solutions.

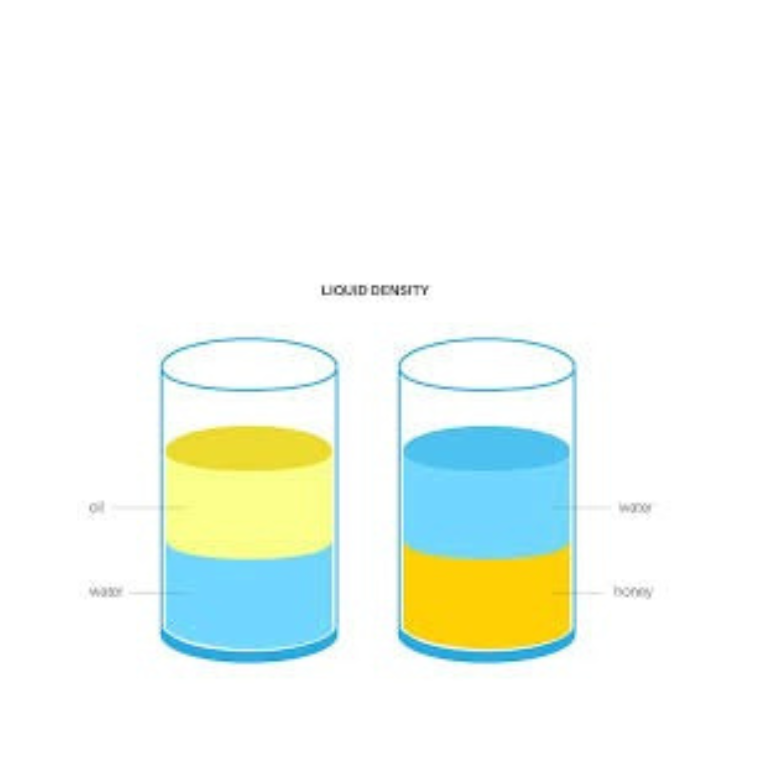

Nylon Polymerization Setup

Hexamethylenediamine in Water

Sebacoyl Chloride in Hexane

Observation:

Click "Start Polymerization" to begin the nylon formation process at the interface.

The Science Behind Nylon Formation

Polymerization Process:

- Step 1: Hexamethylenediamine (aqueous) and sebacoyl chloride (organic) solutions are brought together

- Step 2: At the interface, amine groups react with acid chloride groups

- Step 3: Condensation reaction forms amide bonds (peptide bonds) with HCl byproduct

- Step 4: Polymer chains grow at the interface forming nylon-6,10

Chemical Reaction:

H2N-(CH2)6-NH2 + ClOC-(CH2)8-COCl →

-[HN-(CH2)6-NH-OC-(CH2)8-CO-]n- + HCl

Key Components:

| Component | Role | Chemical |

|---|---|---|

| Aqueous Solution | Provides amine groups | Hexamethylenediamine + NaOH |

| Organic Solution | Provides acid chloride groups | Sebacoyl chloride in hexane |

| Interface | Reaction site | Water/hexane boundary |

Characteristics of Nylon-6,10:

- Type: Condensation polymer (polyamide)

- Properties: Strong, flexible, resistant to abrasion

- Melting point: ~215°C

- Uses: Fibers, bristles, fabrics, ropes

Real-World Applications:

- Clothing and textiles (nylon fabrics)

- Ropes and fishing lines (high strength)

- Carpet fibers (durability)

- Parachutes (lightweight and strong)

- Toothbrush bristles